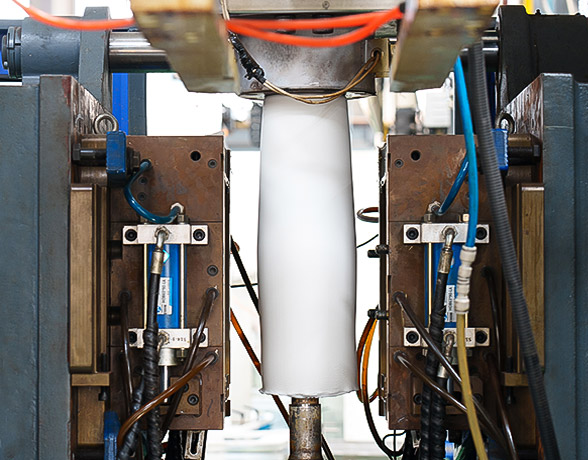

The bottle is in the manufacturing process of fluoride HDPE plastic bottles in adding fluoride, fluoride process, and nitrogen mixed gas to blow in a special blow molding equipment, so that the container with fluoride treatment without the container wall processing on a layer of polyvinyl fluoride material layer, this layer of polyvinyl fluoride material layer minimizes solvent penetration. Ordinary plastic barrel barrier performance is poor, many customers use metal instead of plastic barrels to bloom, but the iron bucket wall and the bottom of the barrel joint leakage, iron material itself is easy to rusts. Compared with ordinary plastic bottles, fluoride bottles can effectively prevent the penetration of organic solvents and product degradation. Is your better choice for chemical products.

Fluorination Process

Fluorinated Bottle Characteristics

-

Effectively prevent organic solvent penetration and product degradation.

-

B

Good performance-to-price ratio.

-

T

The use of high-quality imported raw materials, the world's advanced blow molding equipment production.

-

The unique high barrier effect, the product appearance is very beautiful, and the anti-leakage effect is also very obvious. Having access to the UN (transport organization of the United Nations) certification is the exemption of export packaging.

Product use

-

Gas diesel additives, paint, paint, chemical raw materials, organic solvents, special chemicals, food (flavors and fragrances), ink additives, and other high-value chemicals, etc. Can hold liquid, powder, granules, and paste chemical products. More suitable for foreign customers to send chemical products.

The fluoride bottles as packaging have been widely used in pesticide emulsifiable concentrate and flavor, pharmaceutical intermediates, fine chemicals, etc.

Compared with ordinary plastic bottles, fluoride bottles can effectively prevent the penetration of xylene and organic solvents and product degradation. Is the better choice for chemical products.

Product

Performance

-

Improve the chemical barrier properties, resistance to acid and alkali, and high temperature.

-

Improve the chemical corrosion resistance of the container

-

To avoid the loss of active ingredients in the product

-

Extend the shelf life of the product

-

To avoid contamination of container discoloration

-

To prevent product odor diffusion

-

To avoid the mutual contamination between different products. Fluoride bottles significantly improved the performance of the traditional plastic packaging containers.

Application of Fluorinated Plastics

Nonmetal fluorine is by far active, the more oxidative at ambient conditions, and all of the metal and nondirect reactions generate a variety of fluoride, widely used in electric power, nuclear industry, automobile, medicine, plastics, and electronics industries.

Plastic surface fluorination treatment can improve the quality and scope of application of plastic products, plastic products can improve the effective anti permeability, abrasion resistance, stain resistance, and corrosion resistance, and thus widely used in automotive, medicine, materials, household appliances, cosmetics, and other industries, due to fluorine treatment and role in economic development more important, countries around the world have given much attention.

The use of fluorine plastic de Yun advanced technology, adopting off-line fluoride treatment technology of plastics, rubber packing, the inner surface of the container to make the whole fluorination, the formation of a dense layer covering the inner and outer surfaces, compact and firm. To overcome the common plastic and rubber packing container for organic solvent, gasoline, ink, oil, spices, and other chemicals such as pesticide emulsion infiltration, dissolution, infiltration and volatilization losses caused by pollution, and vessel deformation phenomena.

English

English 中文简体

中文简体 Español

Español عربى

عربى